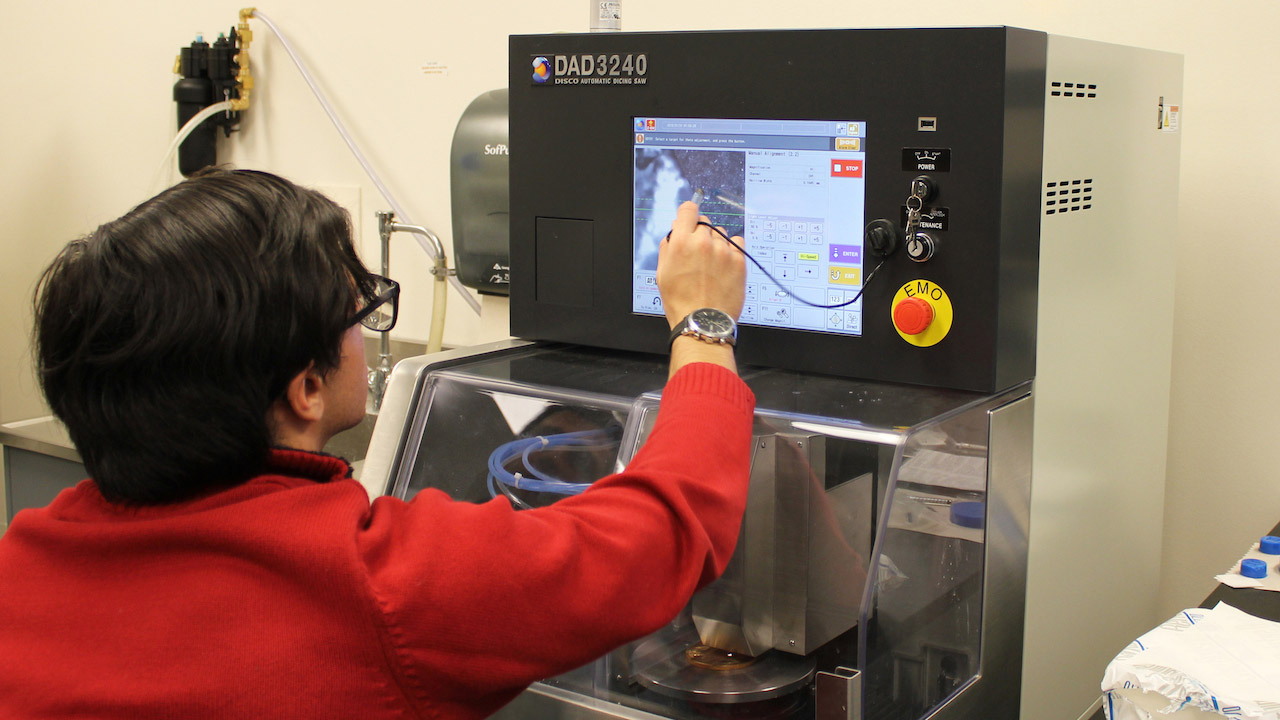

Tool kit: DISCO DAD3240 high-precision dicing saw

Sunnybrook Research Institute (SRI) is the birthplace of some of the most advanced ultrasound imaging equipment on the market. With the recent purchase of the DISCO DAD3240 semi-automatic dicing saw its position as a leading technological hub is further pronounced.

The high-speed, high-precision saw was acquired via Dr. Christine Démoré, scientist in Physical Sciences and the Odette Cancer Research Program at SRI. “Our number-one application of the dicing saw is to make the fine-scale active piezoelectric layers for micro-ultrasound probes,” Démoré says. Her research in capturing high-resolution ultrasound images of the esophagus, achieved by fabricating miniature ultrasound probes with the transducers cut by the dicing saw, is a central example of this.

The machine is an upgrade from the DISCO DAD3220, which has served the SRI community for more than 10 years, and was frequently used to capacity. Although the previous-generation saw is still functional and can continue to be used, the new system adds much-needed dicing capacity and new capability. Users can exercise more precision over a larger workpiece; they can work with wafers or workpieces that are up to eight inches in diameter, as opposed to the previous version’s maximum of six; they can automatically control the water flow, which cools the blade and removes cutting debris; and can more easily cut through thick or layered material with less damage due to the higher power spindle.

Aside from the esophageal project, Démoré says the machine has a wide range of applications. “Where the pathology is too deep to be imaged with current micro-ultrasound imaging probes, but a small endoscope, or even a large needle could be positioned near the tissue of interest, the dicing saw can be used to make a miniature, high-resolution ultrasound probe that fits in the endoscope.”

Démoré’s group isn’t the only one enjoying the advantages of the new machine. The labs of Drs. Brian Courtney, Stuart Foster, Kullervo Hynynen and Meaghan O’Reilly are also frequent users. “Although my group uses it for making ultrasound imaging devices, which generate an acoustic pulse and then detect reflections from tissues to visualize organs and diagnose disease, other groups use it for therapeutic ultrasound devices to generate high-intensity ultrasound beams to treat diseases,” Démoré says.

The dicing saw is operated by graduate students and research assistants, and is used almost every day. Housed in SRI’s device development lab, it was delivered in October 2017 and operational by mid-November 2017.