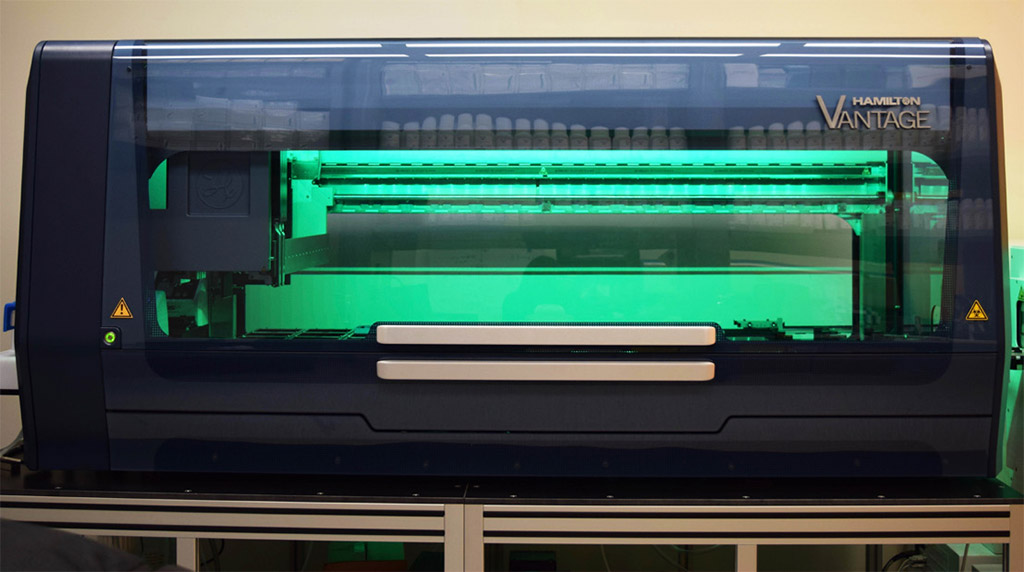

Tool kit: Hamilton automated liquid handling system

Adding to the arsenal of the high-content cellular analysis lab at Sunnybrook Research Institute (SRI) is the Hamilton Microlab Vantage liquid handling system, a robotic system. Under the leadership of SRI’s director of Biological Sciences, Dr. David Andrews, the lab is validating drug targets by identifying small molecules that can be used as drug leads and measuring the sensitivity of patient cells to different combinations of drugs. Andrews’ goal is to personalize therapies to patients.

The system automates the culturing of cells and delivery of reagents (substances used to carry out a lab test) to them. It is designed to work with multiwell plates. Using software that dynamically organizes and performs multiple parallel custom tests, researchers can program methods to manipulate samples in these plates, allowing them to scale up their experiments by working with hundreds or even thousands of reagents.

For the Andrews lab, this functionality is essential. It is looking at whether adding RNA molecules to cells to alter a target gene makes cells more sensitive to chemotherapy, for example. Jarkko Ylanko, who manages the facility, notes the experiments done in the Andrews lab are meant to understand the importance of a particular gene pathway. To do this, several dozen genes need to be silenced in a single experiment. On average, five short-hairpin RNA are needed to knock down a single gene; targeting 100 genes would therefore require 500 reagents.

“Suddenly you’re at the scale beyond which a single person at the lab bench can safely, comfortably, reliably and with great success perform this type of experiment. Through automation, you can set up your experiments on an appropriate scale in microwell plates, and the robot can handle hundreds of things simultaneously,” says Ylanko.

Integrated with the instrument are incubators, where cells and reagents are kept in highly controlled conditions. Soon after manipulation, cells are returned to the incubators, where Ylanko notes they are “happiest.” He says, “We can automate workflows that go over weekends or overnight. Robots don’t eat or sleep, so we don’t have to worry about them needing a break.”

The Andrews lab is the main user, but Ylanko says anyone at SRI that has an assay to work in 96- or 384-well plates can benefit from the automated pipetting done by the robot. The system is being set up for the lab’s RNA research, but interested users should contact him at jylanko@sri.utoronto.ca to determine whether the instrument is suitable for their needs.

In all, the system is worth about $1 million. It was paid for with investment from the Canada Foundation for Innovation and Ontario government.

The high-content cellular analysis lab at SRI is part of the Centre for Research in Image-Guided Therapeutics, also funded by the Canada Foundation for Innovation.